Using vibration condition monitoring to lower costs

Unplanned downtime. High maintenance costs by the reactive (fix it when it breaks) or scheduled (fix it before it breaks) approaches. And premature wear and tear of critical machinery. For your plant and machines leads this to increased operational costs, reduced productivity, and ultimately impacting the overall profitability and reliability of your operations.

-

Reduction in unplanned downtimeReduce unplanned downtime by as much as 30-50%.

-

Maintenance cost reductionReduce maintenance costs by 20-25% by avoiding unnecessary repairs and focusing on issues that are actually developing.

-

Extended equipment lifeExtend the lifespan of critical machinery by 15-20%

-

Operational efficiency gainsIncrease overall equipment effectiveness (OEE) by 5-10%, leading to better throughput and lower per-unit production costs.

Creating Smart Machines

The Vibration Condition Monitoring Solution turns machines into smart, self-monitoring systems. Excessive vibrations or high temperatures often signal issues like imbalance, misalignment, or wear—early indicators of machine failure. Our solution detects these signs early, enabling predictive maintenance and reducing unplanned downtime. Continuous monitoring prevents costly breakdowns, extends equipment life, and improves efficiency while lowering maintenance costs. Real-time data and alerts reduce manual inspections, allowing maintenance teams to address problems proactively.

Automotive manufacturers

Our solution continuously monitors assembly line machinery and prevent costly production halts.

Food and beverage manufacturers

Vibration Condition Monitoring Solution ensures consistent operation of packaging and processing equipment.

Chemical and petrochemical plants

Vibration Condition Monitoring Solution maintains the reliability of pumps, compressors, and rotating equipment critical to operations.

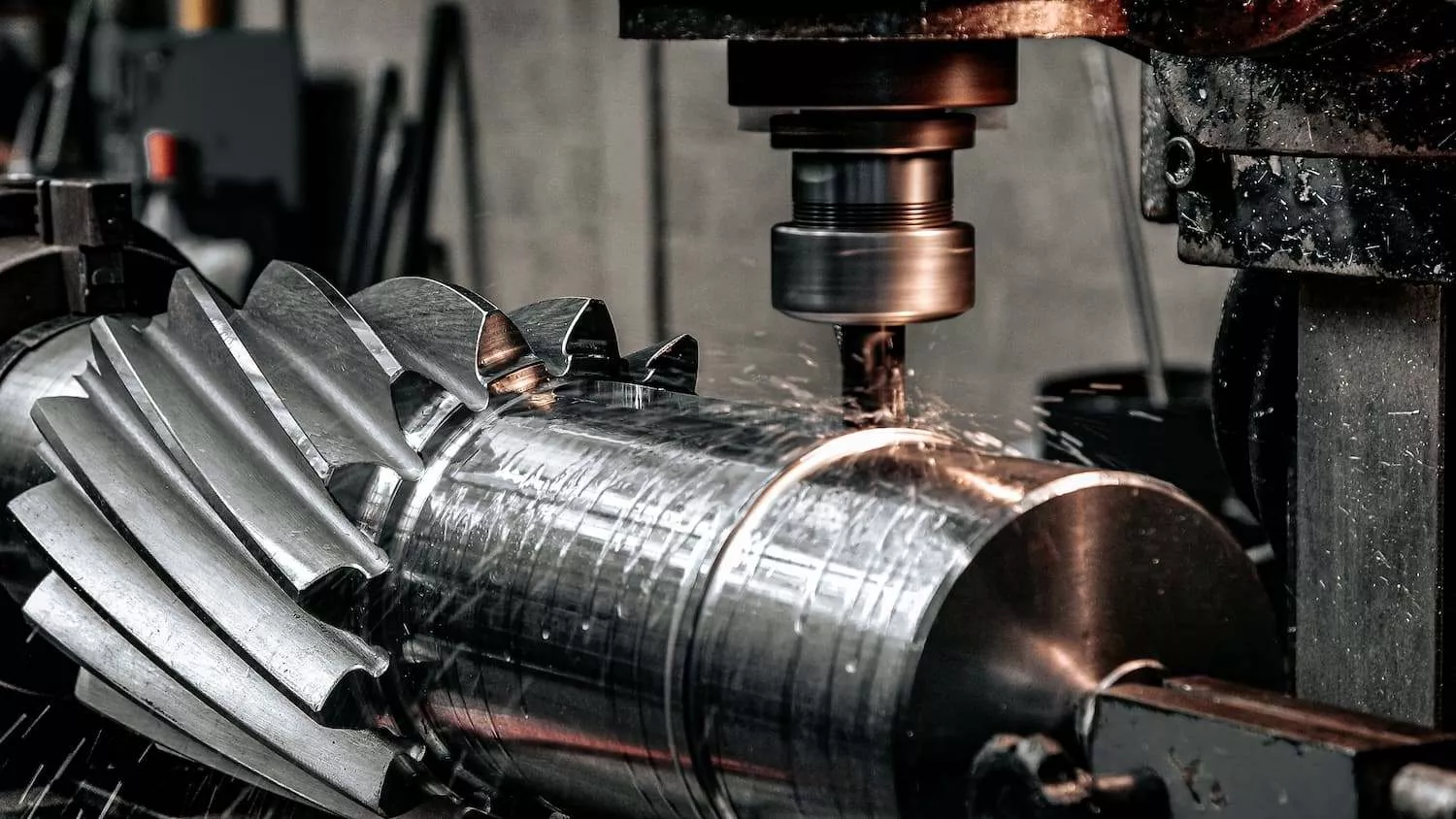

Metalworking and machining

Our solution protects CNC machines and other precision equipment from premature wear or failure.

Vibration condition monitoring solution

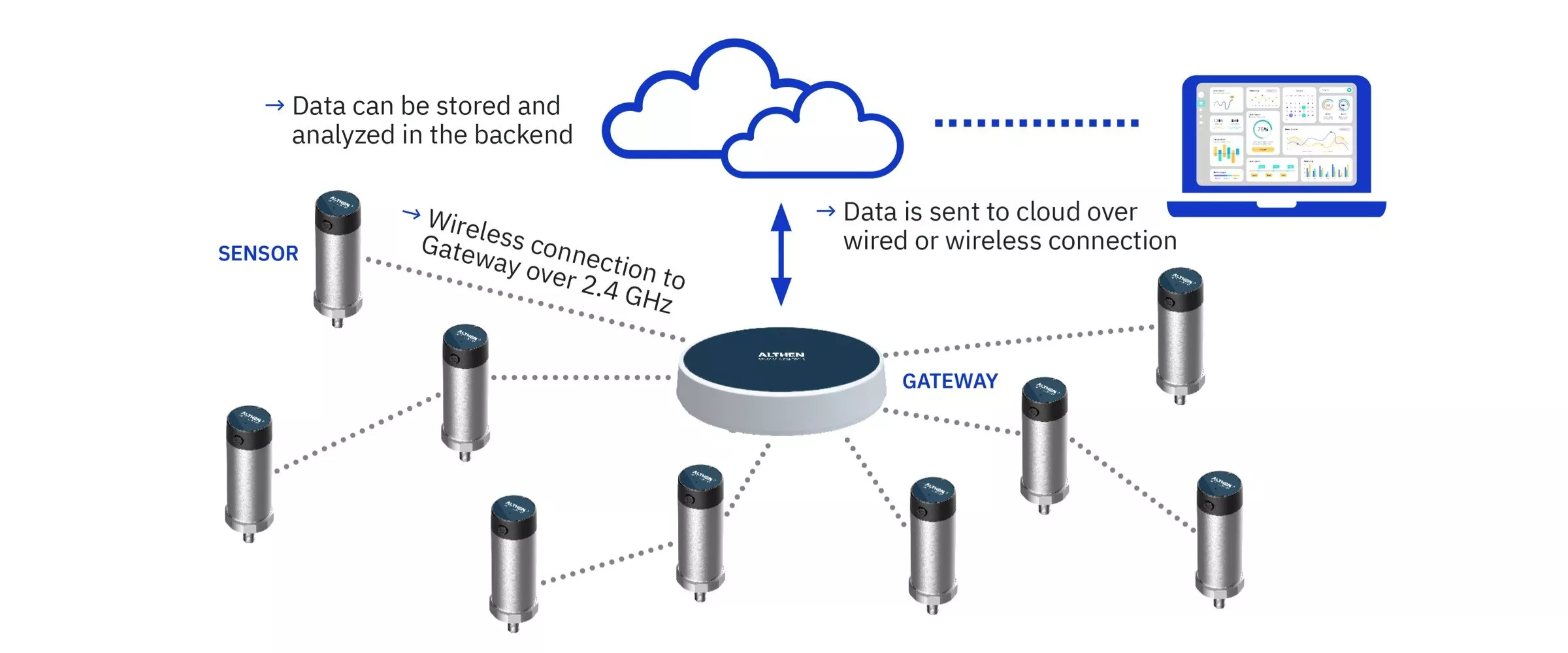

Our solution is a wireless vibration and temperature monitoring system where multiple sensors communicate wirelessly with a central gateway over a 2.4 GHz connection. The data collected from the sensors can either be sent directly to the gateway or, if a sensor is out of range, routed through another device. From the gateway, the data is then transmitted to the cloud using either a wired or wireless connection. Once in the cloud, the data can be stored, analyzed, and monitored in real-time via an online interface, allowing users to gain insights and track system performance remotely.

Experience our solution

Detects and monitor triaxial vibrations and surface temperature and transmit this data The wireless, battery-operated nodes can be easily and cost-effectively installed on existing equipment, and can also integrate into large-scale mesh networks.

- Fully wireless

- Battery driven

- Accurate vibration and also other measurements

The combination of accurate measurements, integrated AI, and ultra-low power consumption makes this a unique and scalable, solution.

Accept the marketing cookies to view this video.

Click here to change your consent.

Network of sensor nodes

The wireless IoT monitoring system comprises a network of sensor nodes that transmit data via an IoT gateway to any computer network or cloud platform. We offer two types of nodes:

- Industrial sensor nodes that measure and monitor triaxial vibrations and surface temperatures of rotating equipment such as pumps, motors, agitators, and mixers;

- Ambient nodes that track air quality, temperature, humidity, ambient light, noise levels, and air pressure.

These wireless, battery-operated nodes can be easily and cost-effectively installed on existing equipment and seamlessly integrated into large-scale mesh networks for data collection in smart buildings, cities, and factories.

Wireless Iot vibration industrial sensor node

- Cost-efficient way to capture vibration and temperature data continuosly

- Easy deployment to existing or new machinery.

- Fully wireless, no need for wiring. Industrial node designed for demanding industrial conditions.

- IP68 protection, making it dust and water proof

Wireless Iot vibration industrial sensor node 6

- Flexible configuration and widely compatible

- Plug and play, fast and easy to deploy on a large scale

- Scalable, thousands of Sensor Nodes can work together

- Frequency range up to 6.3kHz (+/-3dB) with 26667Hz sampling rate

- Nine pre-calculated vibration key parameters for fast assessment

- IP68 protection, making it dust and water proof

Industrial IoT Gateway

For a wired or wireless connection of sensor nodes to backends.

- Can connect to hundreds of sensor nodes

- Supports wired and wireless connectivity

- Stylish in design and compact in size

- ARM Cortex-A8 1GHz Processor

- 1 GB DDR3L RAM

- 16 GB eMMC Storage

- Power supply 5V DC

- Size: ø95mm x 18,3mm

An effective solution for smart automation in maintenance of machines. Minimizing downtime, maximizing efficiency, and keeping your equipment running at peak performance.

Connectivity and communication

Our solution is designed to deliver low-power, high-range, and scalable connectivity, Wireless mesh networking allows reliable and scalable communication between sensor nodes and gateways.

The Industrial Node and sensors use Bluetooth Low Energy (BLE) or similar low-power wireless protocols to transmit data through an IoT gateway to cloud platforms or local networks for real-time monitoring. Mesh networks, such as Wirepas Mesh, ensure scalability and strong connectivity across large areas, even if a node fails, by rerouting data through neighboring nodes. The system also supports long-range communication technologies like LoRaWAN, providing flexibility to integrate with various cloud platforms and enabling remote equipment monitoring over vast distances without extensive wiring.Advanced low-power wireless protocols like Bluetooth Low Energy and Wirepas Mesh deliver real-time monitoring and analytics across large industrial environments. The system’s self-healing mesh network and support for long-range technologies like LoRaWAN ensure reliable, scalable, and seamless connectivity, even in the most complex and expansive setups." management.

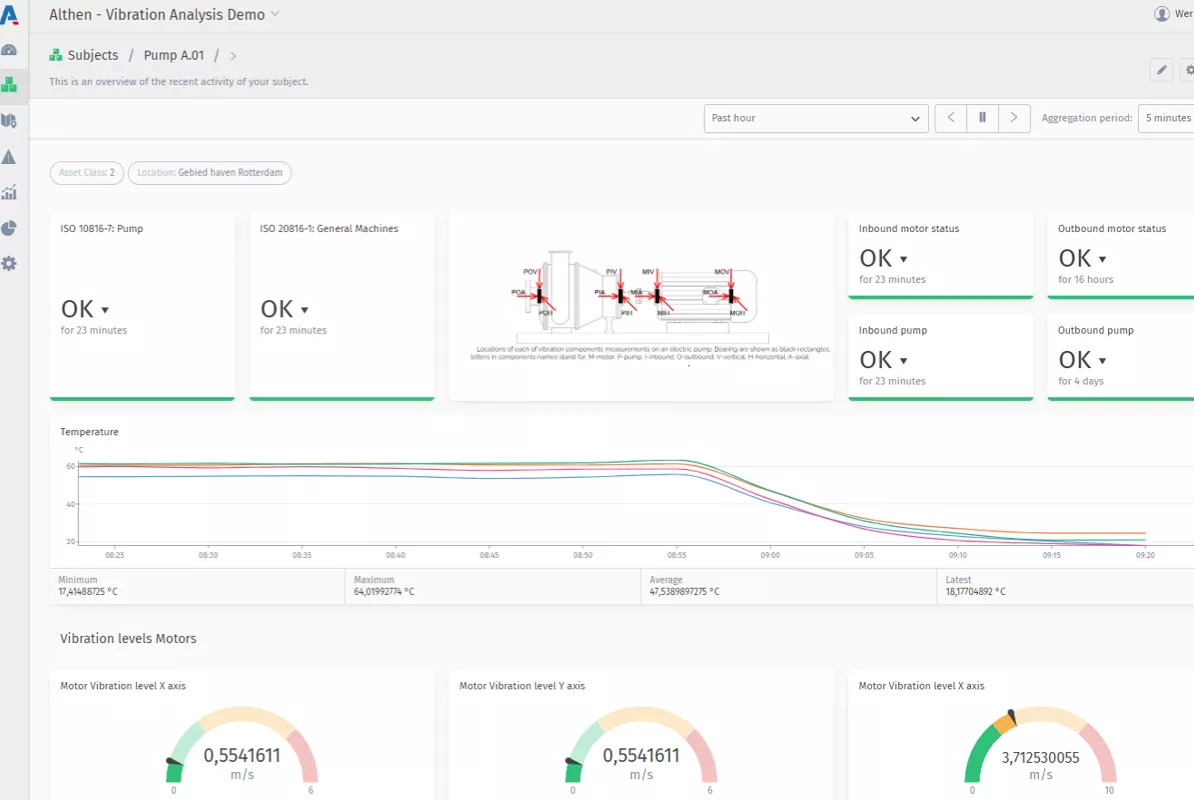

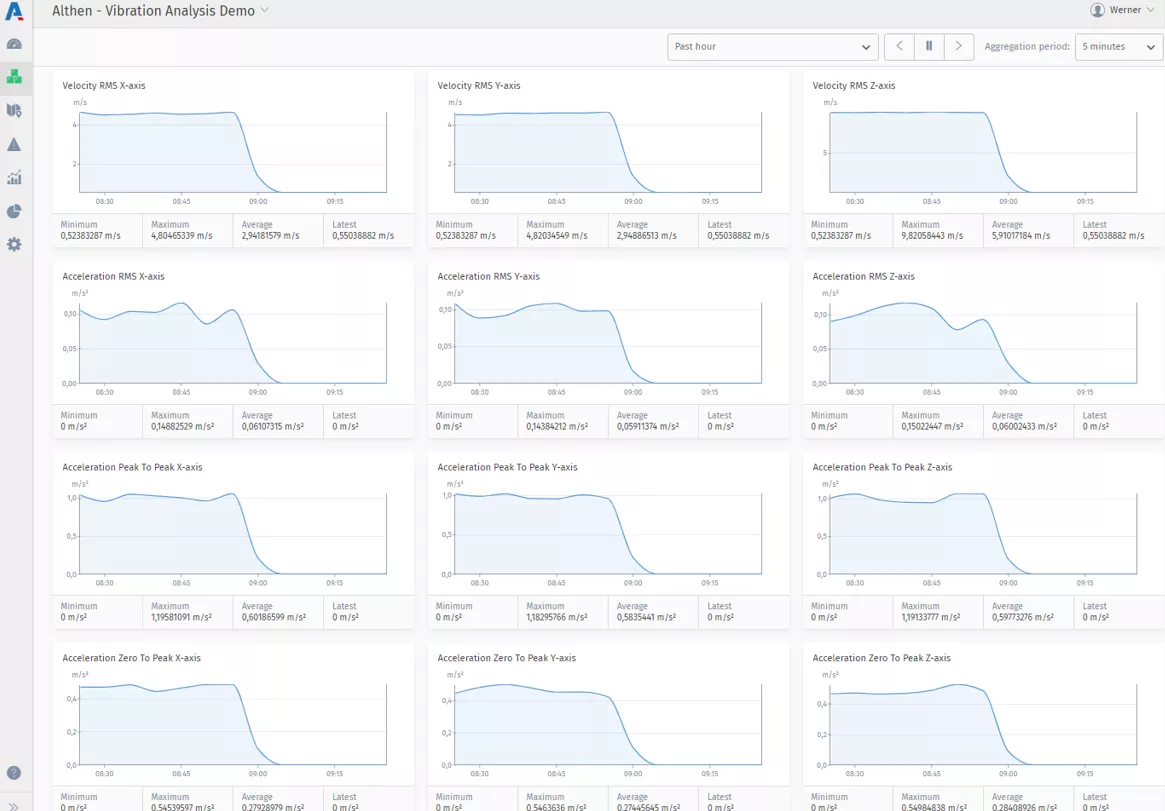

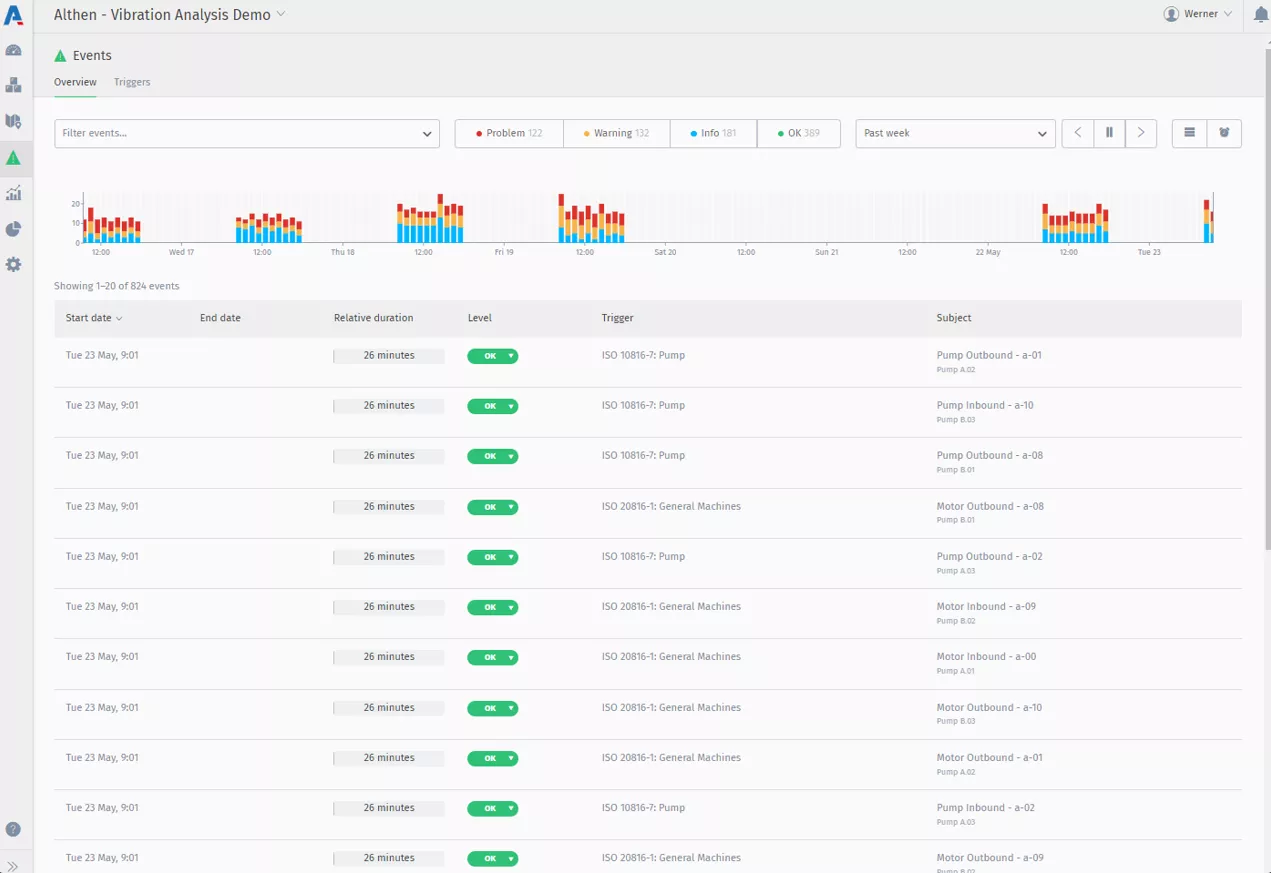

Visualization

Rich data visualization, tailored to your needs:

- A great choice of widgets for different visualizations

- Clear (and fast) overviews for subjects and events

- Powerful filter and aggregation options

- Easy-to-use data explorer to uncover new patterns

- Drill-down on events to more granular levels

- Plant overview with images of your locations/factories/production lines/floors/machines

- FFT analysis

Results guaranteed

Providing value

-

Reduction in unplanned downtime by:40 %

Reduce unplanned downtime.

-

Maintenance cost reduction by:25 %

Orchestrate and work with your sensor data and accompanying algorithms within one central control room.

-

Operational efficiency gains by:10 %

Increase overall equipment effectiveness (OEE) leading to better throughput and lower per-unit production costs.

Monitor your plants and machines

Experience industrial monitoring with cutting-edge IoT solutions from Althen Smart Solutions. Our wireless sensor network provides real-time data, predictive insights, and seamless connectivity to keep your equipment running smoothly, minimize downtime, and maximize operational efficiency. Whether you’re managing a single facility or a large-scale industrial operation, our flexible, scalable system ensures reliable performance even in the most challenging environments.

Take control of your operations today—contact us to learn more about how Althen Smart Solutions can revolutionize your equipment monitoring and elevate your operation and business to new heights.

How can we help you?

Do you need advice or help with your IIoT measurement project?

Our IIoT projects

Whitepaper IIoT

Setting up and commissioning an IIoT solution: from selecting the platform with wireless acceleration sensors to monitoring and commissioning.